Instaflex progress - 24 November 2025

Over the past period, we have made significant progress in advancing the project’s objectives around data-driven insights, system flexibility, and intelligent control of energy systems. We collected, processed, and distributed offline data from selected components at the pilot site, establishing a solid foundation for subsequent analyses and modelling work. In parallel, we prepared a comprehensive overview of the available flexible loads, distributed renewable energy resources, and relevant local meteorological observations. The focus here was twofold: detailed technical characterisation of each asset, and the abstraction of these assets into generic categories to enable systematic flexibility assessment.

Based on this classification, we analysed the potential of the different categories of flexibility assets, including activation costs, operational barriers, and broader non-technical obstacles that hinder their utilisation today. These insights are essential for designing feasible and scalable energy-flexibility solutions.

In addition, we developed a full pipeline for forecasting on-site meteorological variables, specifically tailored for use in reinforcement-learning-based optimisation. We also created a machine-learning framework and corresponding model for forecasting electricity demand, enabling these predictions to be used directly for advanced control and optimisation of energy and control systems.

Finally, we developed and maintained the project website and ensured regular outreach through semi-annual newsletters and LinkedIn updates. Combined with project management and structured internal communication, these efforts have strengthened transparency, visibility, and efficient collaboration within the project team.

With the following link ,, you can download the related deliverables:

Instaflex progress - 5 May 2025

The InStaFlex project is well underway, advancing its mission to unlock industrial flexibility for the benefit of the electricity grid. By focusing on demand-side management of deferrable industrial loads and distributed energy resources across multiple sites, the project aims to contribute to a more resilient and efficient energy system. Beyond technical optimization, InStaFlex also tackles the human and economic dimensions—exploring how to incentivize end-users, manage trade-offs, and empower industries in their interactions with demand aggregators. In parallel, we’re developing tools to quantify the value of flexible assets and to inform policy with actionable insights. Here below, some first insights!

The Role of Models in Control

During InStaFlex, we will intelligently control industrial sites to reduce the electricity costs of companies and to provide flexibility to the Belgian electricity market.

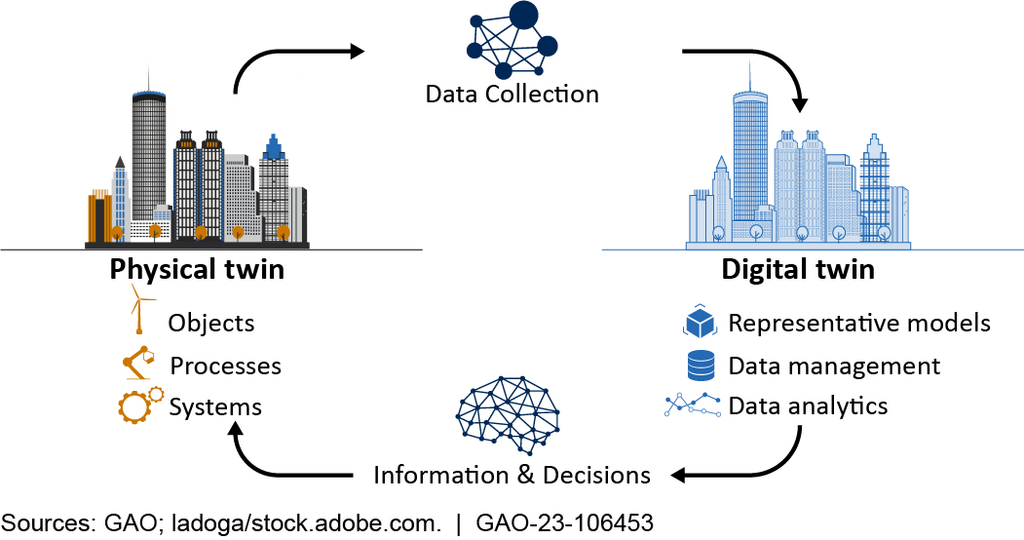

The most advanced control algorithms of today (including Model Predictive Control and Reinforcement Learning) all rely on a digital model of the system to achieve this control.

It goes without saying that the performance of these control algorithms depends on the accuracy of the digital model.

In an ideal world, we would know exactly how each system functions down to the smallest detail, and we could easily transform this information into a digital model. We are indeed witnessing an evolution in which we are getting closer to this ideal world, where everything can be digitally mapped thanks to emerging technologies such as BIM (Building Information Modeling).

Despite this progress, we see that in practice, such detailed models are only available for the most recent buildings. To work around this problem, a combination of system information and data (observations from sensors) is often used in reality. This system information—think, for example, of the functioning of a typical heat pump—is used to create an initial digital model. Data from installed sensors can then be used to improve the accuracy of this model.

In this way, a fairly accurate model can be obtained despite the limited amount of information available from the industrial site.

Photo Voltaic power production forecasting

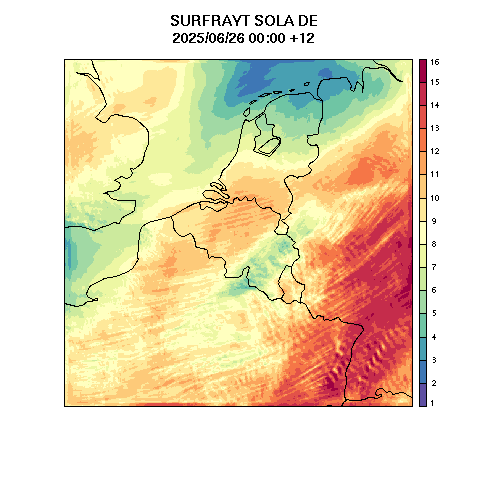

Many industrial sites have assets such as rooftop PV installations, for which the power generation is dependent on the weather. To incorporate this variable solar power generation in energy management actions investigated in the INSTAFLEX project, we need intraday and day-ahead weather forecasts. At the Royal Meteorological Institute of Belgium (RMI), we support this by running high-resolution numerical weather prediction models tailored for regional forecasting. Specifically, we operate the ALARO limited-area model (LAM) at 4 km and 1.3 km resolution, driven by initial and boundary conditions from the global ECMWF IFS model. In addition, we make use of the ECMWF ensemble forecasts at a 9 km resolution to capture the inherent uncertainty in weather conditions and provide a range of possible outcomes.

For PV power production forecasting, key meteorological variables include the direct and diffuse components of downward solar radiation at the surface, as well as air temperature and wind speed, which influence PV panel efficiency. By using ensemble forecasts, we can also go beyond single-value predictions to generate scenarios of PV production. In the INSTAFLEX project, RMI provides multi-site deterministic and ensemble-based PV production forecasts to inform the reinforcement learning (RL) models that will optimize energy management actions across industrial sites. RMI is also investigating the statistical correction of PV forecasts using machine learning techniques. By training models on historical meteorological forecasts, past PV production data, and ground truth measurements collected at INSTAFLEX pilot sites, we aim to enhance the accuracy of the PV forecasts and better quantify the forecast uncertainty, including the correlations between the forecasts at different sites.

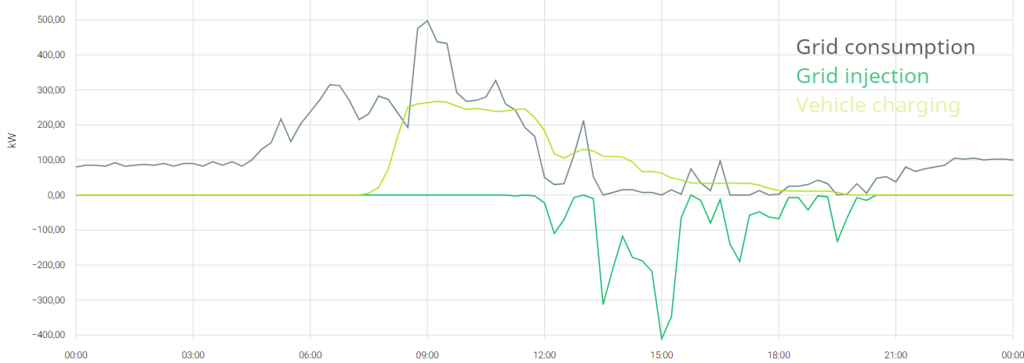

Soft adoption

Many companies have already invested in technology to reduce carbon emissions: solar panels, electric vehicles, heat pumps, but also core process machines such as direct electric kilns. These are the first profitable steps towards a more sustainable and less carbon intensive industry. However, as an energy monitoring company, Oktow sees ‘behind the meter’ how these technologies operate ‘in the wild’. Although each individual technology itself is a good step in the right direction, but it often lacks on coordination and integration. We often see companies running their heat pump from 6 o’clock in the morning until noon, charging cars as soon as they arrive in the morning, consuming energy from the grid. Water treatment plants run on Friday night. And every day a large amount of PV is injected in the grid during noon, when prices are low. The standard approach in industry is currently to install a battery to charge on excess PV energy and reuse it in the evening or during the next morning. This is a very material and capital-intensive investment, while smart control could shift a lot of users to the sunny hours. Although many solutions are emerging, a big challenge remains to correctly estimate the flexibility of these assets: how much energy and with which power profile could be shifted to optimize local PV power or utilize low-cost grid energy. In Instaflex, models will be developed based on real energy data from companies, to better assess flexibility potential. These models can further be utilized to analyze the feasibility to increase buffer size: e.g. increasing the water buffer of a water treatment plant is potentially more viable than a battery with the same energy content. Oktow is the link between research and industry, providing data to researchers and ‘gluing’ cloud control commands to physical assets in demo applications. Oktow focuses also on soft barriers, such as user interaction and perception, as these are often perceived as major steps. Convincing companies their energy consumption pattern can be adjusted without to much practical implications is a big part of change management.